Allen Bradley Pid Tuning Software

Vmware Workstation 7 Serial Keygen And Crack there. What's a PID? A PID loop is a mathematical formula used to drive a process variable toward a particular value (the setpoint) and keep it very close to that value by controlling an output. PID loops are often used in process-oriented applications to control temperature, flow, pressure, or velocity. In temperature control, for example, the PID's formula controls the output to maintain the desired temperature. The loop compares feedback from an input to the desired setpoint, compensates for changes in load, such as an influx of cold air, and adjusts the output accordingly.

• The input is a measurement of process temperature from a temperature sensor (analog input). Maa Tv Mahabharatham Serial Timings. • The setpoint is the desired temperature, perhaps from a thermostat (analog input) or an operator HMI.

PLC Training. Software CD has a final exam, laboratory manual and the ability to print a Certificate of Completion. This computer based training software, is an.

• The output is a heater control (analog output). A PID can control just one isolated system or be part of a larger, cascaded system, where one loop controls the setpoints or input variables of others. PID calculations are complex, and most PIDs require tuning to maximize effectiveness. When you tune a PID loop, you make real-time changes to gain, integral, and derivative values as necessary to stabilize the system and increase efficiency. How do I do PID loop control? If you have an Opto 22 SNAP PAC or, you already have the ability to do PID loop control. Each controller or brain has 96 PID loops built right in.

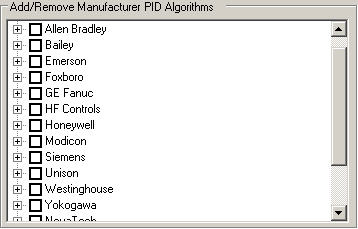

To configure and tune them, you use programming software. • Because PID loop control is built into the distributed I/O unit, PIDs run locally and continue to run even if communication with the controller is interrupted. • Five algorithms are available; you can choose the one you want for each PID loop. • For maximum flexibility, any PID input, setpoint, or output can be determined by commands in your PAC Control program. • The graphical tuner in PAC Control makes tuning a loop much easier. • You can also put PID graphs into your HMI, so authorized technicians can view or even tune a PID loop when needed. PAC Control and PAC Display are both included in the free download.